Retaining Wall Construction: 7 Essential Steps for Stunning Results

The Foundation of Sturdy Landscapes: Building Retaining Walls

Retaining wall construction involves building a structure that holds back soil to prevent erosion and create level areas on sloped terrain. Here’s what you need to know:

- Purpose: Prevents soil erosion, creates usable space on slopes, and improves landscape design

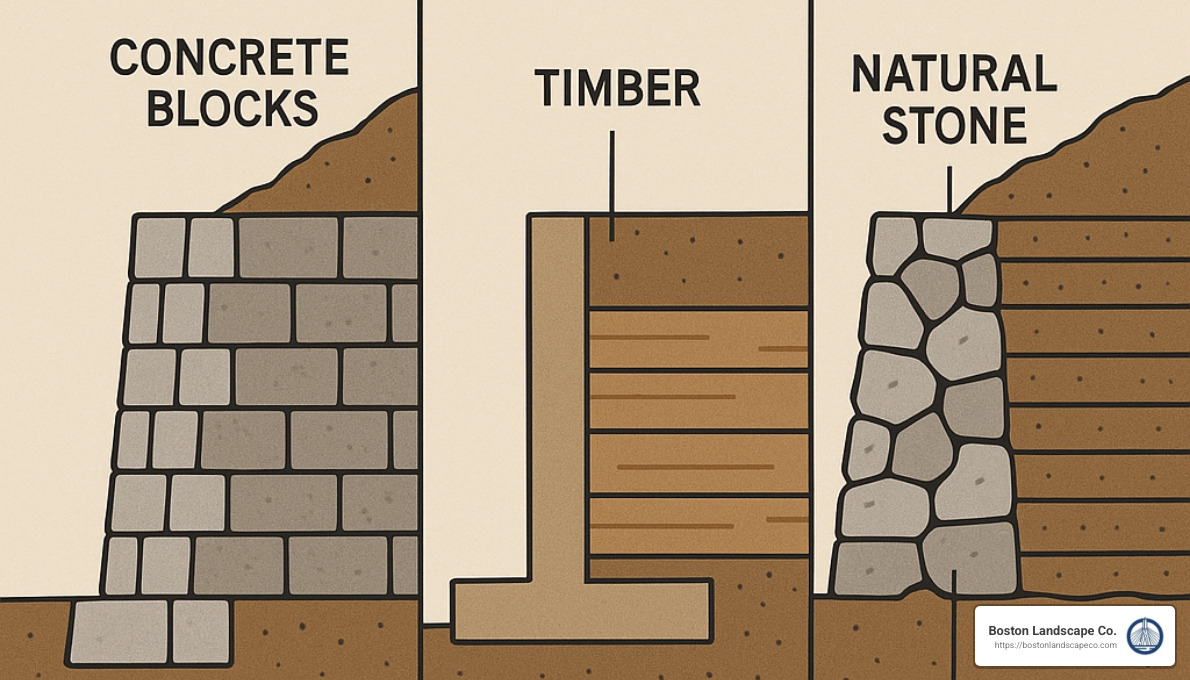

- Materials: Concrete blocks ($20-150/sq ft), timber ($15-135/sq ft), natural stone ($20-250/sq ft)

- Height considerations: DIY suitable for walls under 4 feet; professional engineering required for taller walls

- Basic steps: Planning, excavation, foundation preparation, first course installation, stacking, drainage installation, backfilling

Retaining wall construction is more than just stacking materials—it’s a careful balance of engineering principles and aesthetic design. When built properly, these structures transform unusable slopes into functional spaces while preventing erosion and managing water flow. However, poor construction can lead to bulging, leaning, or complete collapse, potentially causing property damage or safety hazards.

The key to successful retaining wall construction lies in proper planning and understanding the fundamental principles that keep these structures standing strong against the constant pressure of soil and water.

I’m Steve Schumacher, owner of Boston Landscape Co with over three decades of experience in retaining wall construction and landscaping solutions throughout the Greater Boston area. Our company has completed hundreds of retaining wall projects, from simple garden walls to complex engineered systems for steep slopes and challenging terrain.

Quick Retaining wall construction definitions:

Understanding Retaining Walls: Purpose and Types

When you look at a beautifully terraced yard or a sloped driveway that somehow stays perfectly in place year after year, you’re seeing the magic of retaining wall construction at work. These hardworking structures might look simple, but they’re actually engineering marvels designed to battle gravity every single day.

At its heart, a retaining wall does exactly what its name suggests – it retains soil that would otherwise slide downhill. Think of it as nature’s bookend, holding back earth at an angle steeper than it would naturally maintain.

“Retaining walls are designed to restrain soil at an angle steeper than the material’s angle of repose.”

What many homeowners don’t realize is just how much pressure these walls withstand. The soil behind even a modest 4-foot wall can weigh several tons when saturated with water! This is why proper retaining wall construction techniques aren’t just about aesthetics – they’re about safety and longevity.

Types of Retaining Walls

The world of retaining wall construction offers several distinct approaches, each with its own ideal applications. Let me walk you through the main types you’ll encounter:

Gravity retaining walls rely on their own weight and mass to hold back soil. These sturdy structures are typically built from heavy materials like concrete blocks, natural stone, or poured concrete. They work wonderfully for walls up to about 10 feet high, making them perfect for most residential applications. Their relatively straightforward construction makes them a popular choice for DIY enthusiasts with smaller projects.

Cantilever retaining walls are the clever engineers of the retaining wall family. Built in an L-shape with a vertical wall and a horizontal footing that extends under the soil being retained, these walls use physics to their advantage. The weight of the soil itself helps anchor the wall in place. Made primarily from reinforced concrete, cantilever walls can reach heights of up to 16 feet but require moderate to advanced construction expertise.

Anchored walls bring extra reinforcement to challenging situations. When space is limited or you need a particularly tall wall, anchors driven deep into the soil or rock behind the wall provide additional support. These anchors, typically made of steel, connect to the wall face to create a highly stable system. While extremely effective, anchored walls require specialized equipment and professional installation.

Reinforced soil retaining walls (also called Mechanically Stabilized Earth walls) represent modern innovation in retaining wall construction. These walls incorporate layers of geogrid or metal mesh within the backfill soil, creating a reinforced mass that works together with the wall face. This clever approach can reduce construction costs by up to 75% compared to traditional methods while still providing excellent stability for tall walls under significant pressure.

Benefits of Retaining Walls

Beyond their primary job of holding back soil, well-designed retaining walls offer numerous practical benefits that make them worth the investment.

Erosion control stands as perhaps the most critical benefit. By stabilizing slopes and preventing soil movement, retaining walls protect your property from the relentless forces of wind and water that gradually wash away exposed soil. This protection is especially valuable on waterfront properties or homes built on hillsides.

A properly constructed retaining wall also creates increased usable space – turning previously unusable slopes into flat, functional areas for gardens, patios, or play spaces. Many Boston homeowners find that a strategic retaining wall can effectively expand their outdoor living area by 30% or more.

From a design perspective, retaining walls offer wonderful opportunities for landscape design improvement. They create visual interest through different levels, define distinct outdoor rooms, and provide natural transitions between areas of your yard. At Boston Landscape Co., we often incorporate seating walls or planting pockets into our retaining wall construction projects to maximize both beauty and functionality.

Beyond aesthetics, these structures can significantly boost property value. A well-designed retaining wall doesn’t just solve problems – it creates opportunities that future buyers will appreciate. And with proper drainage systems incorporated into the design, retaining walls also contribute to flood prevention by managing water flow and directing it away from structures and foundations.

The key to enjoying all these benefits lies in proper planning and construction. As we like to remind our clients, a well-designed retaining wall must account for tens of tons of saturated soil pressure – highlighting why proper engineering and construction techniques are absolutely critical for long-term success.

For more information about our hardscaping services, including expert retaining wall construction, visit our Hardscaping Services in Boston page.

Key Factors in Retaining Wall Construction

When it comes to building a retaining wall that will stand the test of time, there’s a lot more to consider than just stacking some blocks or stones. I’ve seen many DIY walls fail because homeowners overlooked critical factors that professionals know to address from day one. Let’s walk through what really matters when planning your retaining wall construction.

The soil behind your wall is literally pushing against it every day. Different soil types create different challenges. Clay soils hold more water and push harder against your wall, while sandy soils drain better but might not provide as much stability. Rocky soils offer excellent drainage but can be a real workout during excavation! As we often tell our clients, even small variations in soil composition can dramatically change how we approach the reinforcement and design of your wall.

The height of your wall is another crucial factor. For walls under 4 feet, you might be able to tackle it as a DIY project using simple gravity wall techniques. But once you go higher than that, you’re entering professional territory – these walls need proper engineering to ensure they won’t fail. Sometimes, instead of building one tall wall, we recommend a tiered approach with multiple shorter walls, which can actually look more attractive while being safer and more stable.

Do You Need a Permit for Retaining Wall Construction?

This is one of the most common questions we hear, and the answer is: it depends, but probably yes if your wall is of any significant size. Most local building departments require permits for walls over 3 feet tall. This isn’t just bureaucratic red tape – it’s about ensuring your wall won’t become a safety hazard.

In Massachusetts communities like Boston, Lexington, and Stoneham where we regularly work, you’ll typically need a permit if:

- Your wall will hold back more than three feet of soil

- The wall will experience additional pressure from factors like vehicle traffic nearby, neighboring structures, or being built on a slope

- You’re creating a terraced design with multiple walls affecting each other

For more complex projects, be prepared to provide engineering calculations, soil reports, and detailed drawings. It might seem like a hassle, but these requirements exist to keep your property and your neighbors safe. If you’re looking for other hardscaping services in Boston, you can learn more about what we offer at Boston Landscape Co’s Hardscaping page.

Water is the silent enemy of retaining walls. In fact, improper drainage is the number one reason walls fail. When water builds up behind a wall, it creates tremendous pressure – hydrostatic pressure – that can cause even well-built walls to bulge or collapse. A proper drainage system includes a perforated pipe at the base, plenty of gravel backfill, filter fabric to keep soil from clogging the system, and proper grading to direct water away from the top. Never skip on drainage – it’s like insurance for your wall’s longevity.

Selecting Materials for Your Retaining Wall

The materials you choose affect not just how your wall looks, but how it performs and what it costs. Here’s a straightforward breakdown of your main options:

Concrete Blocks are versatile workhorses in retaining wall construction. They come in various styles and colors, from basic gray blocks to those that mimic natural stone. They typically cost between $20-150 per square foot, based on internet data (not Boston Landscape Co. pricing). The higher-end blocks can create truly stunning walls that blend beautifully with your landscape.

Timber offers a warm, natural look that many homeowners love. It’s relatively DIY-friendly and costs about $15-135 per square foot according to internet averages (not our pricing). The downside? Even pressure-treated wood eventually succumbs to the elements, giving these walls a lifespan of around 15-20 years. They’re best for lower walls in areas that aren’t too wet.

Natural Stone creates the most neat, timeless retaining walls. There’s something authentic about a well-built stone wall that concrete products simply can’t match. This premium option typically runs $20-250 per square foot based on internet data (not our pricing). Stone walls require significant skill to build properly but can last for generations when constructed correctly.

Interlocking Concrete Blocks offer the best of both worlds – the strength of concrete with relatively simple installation since they don’t require mortar. They typically cost $25-165 per square foot according to internet data (not our pricing). These systems often include specific pieces for corners and caps, making for a clean, finished look.

Here in New England, where we experience everything from summer heat to freeze-thaw cycles in winter, we’ve found that quality concrete block systems typically offer the best balance of durability, appearance, and value for most homeowners. That said, the right choice always depends on your specific property, design preferences, and budget.

At Boston Landscape Co., we take the time to evaluate all these factors before recommending the best approach for your retaining wall construction project. A well-built retaining wall isn’t just functional – it becomes a defining feature of your landscape that you’ll appreciate for years to come.

Step-by-Step Guide to Retaining Wall Construction

Now that we’ve covered the essentials, let’s roll up our sleeves and walk through the actual process of building a retaining wall. I’ve helped hundreds of homeowners transform their sloped yards into beautiful, functional spaces, and I’m excited to share what works.

Planning and Designing Your Retaining Wall Construction

The planning phase might not be the most exciting part, but it’s absolutely crucial for success. As one landscape architect I work with always says, “Careful attention to planning and design ensures a quality finished wall.”

Before you touch a single block or timber, take time to thoroughly assess your site. Consider exactly what you need this wall to accomplish—whether it’s controlling erosion on that troublesome slope, creating a flat area for your new patio, or simply adding visual interest to your landscape.

Walk your property and note the existing slope, soil conditions, and any structures or utilities that might affect your wall placement. Pay attention to how water moves across your property during rainstorms, as this will inform your drainage plans.

With your basic concept in mind, grab your measuring tape and start calculating. You’ll need accurate measurements for the wall’s length and height to determine material quantities. Always add about 10% extra for waste—trust me, you’ll be glad you did when you’re not making that emergency run to the supply yard mid-project!

Creating a detailed layout is your next step. I like to use stakes and string to mark the wall location, which helps visualize the finished project and ensures proper alignment. This is especially important if your wall will have curves or corners, which require special attention.

Before you start digging, check with your local building department about permits. As Scott McBride wisely notes, “Building durable retaining walls of 6×6 pressure-treated timbers isn’t complicated. If you built with Lincoln Logs as a kid, you know the basics.” While that’s true in concept, regulations still apply—especially for walls over 3 feet tall. And don’t forget to call 811 to locate underground utilities before you start excavating!

Preparing the Foundation for Retaining Wall Construction

If there’s one thing I’ve learned in my years of retaining wall construction, it’s that the foundation makes or breaks your project. As one industry expert told me, “Every manufacturer and consultant we contacted stressed the absolute necessity of starting with a solid, level and well-compacted base.”

Start by excavating a trench that’s proportional to your wall height—generally about 12 inches wide for every 8 inches of wall height. The trench should be deep enough to bury at least half the height of your first block, plus an additional 6 inches for your base material. This might seem excessive, but proper foundation depth prevents shifting and settling that can ruin your wall over time.

Once your trench is dug, it’s time to add your base material. I recommend using crushed stone or gravel with angular, sharp-edged particles (¾-inch minus works great) because it compacts better than rounded stones. Add 4-6 inches of this material, but don’t dump it all at once! Work in thin layers of 2-3 inches, thoroughly compacting each layer before adding the next. This step is where many DIYers cut corners, but proper compaction is absolutely worth the extra effort.

Getting your base perfectly level is critical. Even small irregularities in your base will become magnified as you build upward. Use a long straight board with a level on top to check for evenness across the entire length. Take your time here—adjusting your base is much easier than trying to fix a leaning wall later!

For some block systems, adding a thin layer of coarse sand on top of your compacted base can help with fine-tuning the level. Drag a straight board across this layer (a technique called “screeding”) to create a perfectly flat surface for your first course of blocks.

Finally, install landscape fabric in your trench, extending it up the back of the excavated area. This often-overlooked step prevents weeds from growing through your wall and keeps soil from mixing with your drainage material—a small effort that pays big dividends in the long run.

Building the Wall Structure

With your foundation prepared, it’s time for the most satisfying part of retaining wall construction—actually building the wall! This is where your project starts to take shape and your vision becomes reality.

Begin by carefully placing your first course of blocks or timbers on the prepared base. This initial row is arguably the most important, as it provides the foundation for everything that follows. Take your time to ensure each unit is perfectly level from front to back and side to side. I like to use a rubber mallet for gentle adjustments without damaging the materials. For blocks with lips or flanges designed to create setback, you’ll typically remove these from the first course only.

While working on this crucial first row, regularly check alignment using a string line stretched from end to end. Small misalignments now will become major problems later, so be meticulous. I always tell my crew that you can’t rush this step—the time invested here pays off throughout the rest of the project.

As you move to subsequent courses, create strength through proper staggering. Each block should bridge the joint between the two blocks beneath it by at least ¼ of the block length. This creates what masons call a “running bond” pattern that significantly strengthens your wall. For gravity wall systems, each course should step back slightly (typically about ¾ inch) to help the wall resist the pressure of the soil behind it.

You’ll likely need to cut some blocks to fit at the ends or for curves. Use a masonry saw, chisel, or block splitter for clean cuts, and always wear proper safety equipment—your eyes and lungs will thank you! I’ve seen too many DIYers skip the safety glasses, which is a mistake you only make once.

For walls over 3 feet tall, reinforcement becomes crucial. This might include geogrid fabric, rebar, or tiebacks, depending on your wall system and engineering requirements. These reinforcement materials extend into the backfill to create a unified, stable mass that resists the pressure of the soil. Follow the manufacturer’s specifications carefully here—this isn’t an area where improvisation pays off.

Throughout the building process, periodically step back and look at your work from different angles. Small adjustments early on prevent major headaches later, and taking this broader view helps ensure your wall is developing the way you envisioned.

Ensuring Proper Drainage to Prevent Wall Failure

I can’t emphasize this enough: proper drainage is the secret to a long-lasting retaining wall. In my 30+ years of retaining wall construction, I’ve seen more failures from poor drainage than from any other cause. As one engineering report bluntly states, “To a degree, dry soil is self-supporting. The real test begins when water saturates the soil, making it semiliquid and less able to support itself.”

Start your drainage system with a perforated pipe (typically 4-inch diameter) placed at the base of the wall. This pipe should be wrapped in filter fabric to prevent clogging from fine soil particles. Ensure the pipe has a proper outlet where water can exit—either daylighting on a slope or connecting to an existing drainage system. For longer walls (over 50 feet), we typically install multiple drainage outlets to ensure water has several paths to escape.

Behind your wall, create a drainage zone using clean, crushed stone. This material should extend at least 12 inches behind the wall and run from the base to near the top. The stone allows water to flow freely down to the drainage pipe instead of building up pressure behind your wall. Wet soil can exert two to three times more pressure than dry soil—a force that can cause even well-built walls to fail.

Between your drainage stone and the backfill soil, install landscape fabric as a separator. This simple layer prevents soil from washing into and clogging your drainage material, while still allowing water to pass through. Make sure this fabric extends from the base to the top of your drainage zone for complete protection.

When backfilling, work in manageable layers of 6-8 inches, compacting each thoroughly before adding the next. This methodical approach prevents settlement that could create low spots where water collects. Keep heavy equipment at least 3 feet away from the back of your wall to avoid applying excessive pressure that could cause shifting or bulging.

Finally, proper grading at the top of your wall directs surface water away rather than letting it seep down behind the structure. Create a cap of 8-12 inches of compacted, less permeable soil at the top that slopes gently away from the wall. This simple step can dramatically reduce the amount of water entering your drainage system in the first place.

For more technical details on drainage systems, This Old House has an excellent article on Engineering a Retaining Wall that I often recommend to clients who want to understand the engineering principles involved.

Finishing Touches and Aesthetics

The final phase of retaining wall construction is where your wall transforms from a functional structure into a beautiful landscape feature. These finishing touches not only improve appearance but also contribute to the wall’s longevity and integration with your overall landscape design.

Cap stones are the crown jewel of your retaining wall, providing a finished look while serving practical purposes. These top pieces usually overhang the face of the wall slightly (about 1-1.5 inches) to create a drip edge that prevents water from running down the wall face. Secure these caps with construction adhesive specifically designed for landscape blocks—regular construction adhesive may break down over time with outdoor exposure. A properly installed cap not only looks more polished but also helps protect the blocks beneath from water infiltration.

With your wall structure complete, turn your attention to the surrounding landscape. Final grading around your wall ensures proper drainage away from the structure. Add topsoil as needed in planting areas, making sure all drainage outlets remain clear and unobstructed. This is also the time to repair any lawn areas that may have been damaged during construction.

Thoughtful landscaping around your wall helps it blend naturally with your yard. Consider adding plants that complement the wall’s appearance while helping to prevent erosion. For the top of the wall, I often recommend low-maintenance plants that won’t require frequent watering (which could affect the wall’s stability). Ground covers on slopes above and below the wall can provide additional erosion control while adding visual interest.

For evening enjoyment, consider adding landscape lighting to highlight your wall. Low-voltage systems are relatively easy to install and can dramatically improve the nighttime appearance of your outdoor space. Strategic lighting not only showcases your beautiful new wall but also improves safety by illuminating changes in elevation.

Before considering your project complete, conduct a final inspection of the entire wall. Check for proper alignment, ensure all blocks are secure, and verify that drainage systems are working correctly. This final quality check gives you peace of mind that your wall is not only beautiful but built to last.

At Boston Landscape Co., we believe these finishing details are what separate good retaining wall construction from truly exceptional work. We take pride in creating walls that not only solve practical problems but become standout features that improve the beauty and value of your property. If you’re interested in our approach to hardscaping, you can learn more about our Hardscaping Services in Boston on our website.

Special Considerations for Retaining Walls Over 4 Feet

When your retaining wall project exceeds 4 feet in height, you’re entering a whole new territory of construction requirements. These taller walls aren’t just scaled-up versions of smaller projects – they face dramatically increased soil pressure and require specialized approaches to ensure safety and longevity.

Engineering Requirements

I can’t stress this enough – retaining wall construction over 4 feet tall isn’t typically a DIY project. Most local building codes require plans stamped by a licensed engineer, and for good reason. The forces at work in taller walls can be tremendous, especially after heavy rain when soil becomes saturated.

A professional engineer will conduct structural calculations that account for soil pressure, water loads, and site-specific conditions. They’ll provide detailed construction drawings specifying exactly what materials to use, proper dimensions, and critical reinforcement placement. This might seem like an added expense, but it’s actually an investment in safety and longevity.

In many cases, soil testing becomes necessary to determine the exact properties of your site’s soil and its bearing capacity. Different soil types respond differently to pressure and moisture, so this knowledge is crucial for proper design. The permitting process also becomes more rigorous, often requiring more extensive documentation and possibly inspections at various stages during construction.

At Boston Landscape Co., we’ve guided countless homeowners through this process, connecting them with trusted engineers while ensuring the final design meets both structural requirements and aesthetic goals.

Reinforcement Methods in Retaining Wall Construction

The secret to successful retaining wall construction for taller walls lies in proper reinforcement. Think of reinforcement as the hidden strength that allows these walls to stand strong against enormous pressure.

Geogrid reinforcement is perhaps the most common method we use for taller walls. This synthetic mesh material looks a bit like fishing net but is incredibly strong. We lay it horizontally into the backfill at specified intervals (typically every 1-2 courses), extending it back into the soil behind the wall. This creates what engineers call a “reinforced soil mass” – essentially turning the soil itself into part of the wall structure. The length of geogrid needed is determined by engineering calculations, but it typically extends back from the wall face a distance equal to 60-70% of the wall height.

For timber walls, we often use tiebacks and deadmen. These are anchors that extend from the wall face into the backfill soil. A “deadman” is typically a piece of timber placed perpendicular to the wall and connected to the face with galvanized hardware. These provide crucial resistance against the wall tipping forward under pressure.

In some specialized situations, particularly when stabilizing existing slopes, soil nailing might be employed. This technique involves driving steel reinforcement bars into existing soil and often combining them with a shotcrete (sprayed concrete) facing. This specialized approach requires specific equipment and expertise.

For concrete or block walls, concrete reinforcement using rebar placed within concrete or block cores creates a unified structural system. The pattern and spacing of this reinforcement follows specific engineering guidelines to ensure proper strength.

What’s fascinating is that properly reinforced soil walls can actually cut construction costs by up to 75% compared to traditional retaining wall types, while potentially cutting build times in half. This makes proper reinforcement not just a safety necessity but often a cost-effective approach as well.

Construction Techniques for Taller Walls

Building taller walls requires modified construction techniques starting from the ground up. The foundation requirements change significantly as walls get higher. We typically need deeper and wider foundations that may include concrete footings with rebar reinforcement. The width often extends well beyond the wall face to provide adequate support against tipping.

For walls built on slopes, we frequently use stepped foundations. Each step must be perfectly level and properly compacted, with reinforcement continuing through each step. This approach allows the wall to follow the natural terrain while maintaining structural integrity.

Drainage becomes even more critical with taller walls. The increased soil mass behind the wall means more water pressure can build up. We often install multiple drainage layers, larger diameter drainage pipes, and more extensive filter fabric systems. In some cases, we’ll add surface water management systems to direct runoff away from the wall entirely.

The backfill material itself often changes for taller walls. We may use engineered backfill with specific properties rather than native soil. This material is placed in layers with precise compaction requirements – sometimes requiring testing during installation to verify proper density.

Here at Boston Landscape Co., we’ve built countless retaining walls throughout the Greater Boston area, from Stoneham to Lexington and beyond. When projects require taller walls, we work closely with structural engineers to ensure every wall meets all safety requirements while achieving the aesthetic and functional goals our clients desire. The result is a beautiful landscape feature that will stand strong for decades to come.

Average Costs of Retaining Wall Construction

When planning your retaining wall construction project, understanding the potential costs involved helps you set a realistic budget. I’ve seen countless homeowners surprised by price variations, which is why I want to share a comprehensive overview of what you might expect to pay.

Let me walk you through the typical costs you might encounter for different materials and project elements. That these figures represent average costs based on internet data, not Boston Landscape Co. pricing, and can vary significantly depending on your specific needs.

Material Cost Ranges

The material you choose for your retaining wall significantly impacts your budget. In my experience working with Boston homeowners, I’ve found that material preferences often reflect both practical needs and aesthetic vision.

Concrete Block Walls offer excellent durability and versatility. Basic concrete blocks typically run between $20-60 per square foot, making them a popular mid-range option. If you’re looking for something with more visual appeal, decorative concrete blocks with textured faces or varied colors might cost between $25-150 per square foot. These blocks offer moderate installation complexity, making them accessible for some DIY enthusiasts, though professional installation ensures proper structural integrity.

Timber Retaining Walls provide a natural, warm aesthetic that blends beautifully with New England landscapes. Pressure-treated timber walls generally cost $15-45 per square foot, making them one of the more budget-friendly options. For those seeking premium wood options, cedar or redwood walls run $25-135 per square foot. While relatively simple to install compared to other materials, timber walls require careful attention to proper drainage and treatment to maximize their lifespan.

Natural Stone Walls create a timeless, neat look that many Boston area homeowners prefer. Dry-stacked stone walls (a New England tradition) typically cost $20-85 per square foot, while mortared stone walls range from $30-250 per square foot. These walls require considerable skill to construct properly, especially for larger projects, but the results can be stunning and last for generations when built correctly.

Poured Concrete Walls offer exceptional strength for challenging sites. Basic poured concrete walls generally cost $30-80 per square foot, while decorative options with textured formwork or integral coloring range from $40-150 per square foot. These walls require significant expertise to construct, including proper formwork, reinforcement, and concrete finishing skills.

Gabion Walls provide a contemporary, industrial look using wire baskets filled with stone. Standard gabion walls typically cost $25-75 per square foot, while designer versions with carefully selected stone and premium baskets might run $40-120 per square foot. These walls offer moderate installation complexity and excellent drainage properties.

Cost Factors Beyond Materials

The full picture of retaining wall construction costs extends well beyond just the materials themselves. In my years of experience, I’ve found these additional factors often have a substantial impact on the final project cost:

Wall Height and Length dramatically affect material quantities and construction requirements. Taller walls need deeper foundations and often require engineered reinforcement, substantially increasing costs. It’s sobering to realize that a seemingly modest 4-foot-high, 15-foot-long wall could be holding back as much as 20 tons of saturated soil – that’s why proper construction is so crucial.

Site Conditions can make or break your budget. Sloped terrain requires more extensive excavation work, while poor soil might necessitate improved foundation systems. Limited access for equipment might mean more manual labor hours. I’ve seen projects where removing existing vegetation, rocks, or old structures added significant costs that weren’t initially anticipated.

Drainage Systems are absolutely essential for long-term wall performance. Basic drainage solutions typically cost $10-30 per linear foot, while complex water management systems might run $20-60 per linear foot. This is one area where cutting corners inevitably leads to problems – proper drainage prevents the hydrostatic pressure that causes most wall failures.

Professional Services often represent necessary investments for larger projects. Engineering services generally cost $500-2,500 depending on wall complexity. Permit fees vary widely by location, typically ranging from $100-1,000. For challenging sites, soil testing ($300-1,200) provides crucial information for proper design. While these costs might seem optional for smaller projects, they provide essential guidance for walls over four feet tall.

Additional Features transform a basic wall into a landscape focal point. Integrated lighting systems ($2,000-5,810) create dramatic evening ambiance. Built-in seating ($25-75 per linear foot) adds functionality to your outdoor space. Steps and stairs ($45-125 per step) improve accessibility between levels. Planters ($35-95 per square foot) soften the wall’s appearance with greenery. These improvements, while optional, often make the difference between a merely functional wall and one that improves your outdoor living experience.

“Average costs based on internet data can vary widely, with high-end materials being at least 3x the average pricing.”

At Boston Landscape Co., we believe in transparency throughout the estimation and construction process. While these figures provide general guidelines, your specific project requirements will determine the actual cost. In our experience, investing in quality materials and proper construction techniques generally proves more economical in the long run by preventing the need for costly repairs or complete rebuilds.

Would you like to discuss how we can create a beautiful, durable retaining wall that fits your specific needs and budget? We’re happy to provide a detailed quote custom to your property’s unique requirements.

Maintenance Tips for Long-lasting Retaining Walls

Your retaining wall construction project represents a significant investment in your property’s beauty and functionality. Like any valuable addition to your landscape, it needs proper care to stand the test of time. I’ve found that a little regular attention goes a long way toward preventing costly repairs down the road.

Regular Inspection

Think of your retaining wall as a silent sentinel, constantly working against the forces of nature. It deserves a good check-up at least twice a year—I recommend spring and fall—and after any major storms.

When I inspect walls for our clients, I first look for any signs of movement. Even small shifts can signal bigger problems developing beneath the surface. A slight lean or bulge that wasn’t there before might not seem alarming, but catching these early can save thousands in repairs. I’ll often bring a level to check that everything remains properly aligned.

Drainage issues are the number one enemy of retaining wall construction. During your inspection, make sure all drainage outlets remain clear and functioning. If you notice water pooling near your wall, that’s a red flag that needs immediate attention. One of the most revealing times to check your wall is actually during or just after a rainstorm—you’ll see exactly how water moves around your structure.

Don’t overlook cracks or damage. While hairline cracks in concrete walls might be normal, larger openings or displaced blocks deserve professional attention. Also check for any soil washing out from behind or underneath the wall—this erosion can quickly undermine your wall’s stability.

Preventive Maintenance

An ounce of prevention truly is worth a pound of cure when it comes to retaining wall construction.

Proper drainage maintenance is your wall’s best friend. I recommend clearing drainage pipes annually—typically in early spring after winter’s freeze-thaw cycles. Remove any leaves, soil, or debris that might have accumulated behind the wall or in drainage areas. And don’t forget about downspouts from your home’s gutters—they should direct water well away from your retaining wall.

Vegetation management plays a bigger role than many homeowners realize. Those beautiful mature trees might look great near your wall, but their expanding root systems can exert tremendous pressure over time. Keep large or deep-rooted plants at least 3-4 feet away from your wall. For slopes above or below the wall, consider low-maintenance ground covers that help prevent erosion without threatening the structure. And be mindful of irrigation—excessive watering near your wall can saturate the soil and increase pressure.

Addressing small issues promptly can prevent them from becoming major headaches. Replace any damaged blocks or timbers as soon as you notice them. Fill small cracks before they have a chance to expand. And if you notice minor erosion starting, add some additional soil and erosion-control plants before the problem worsens.

Seasonal Maintenance

Living in New England means your retaining wall faces distinct seasonal challenges that require specific maintenance approaches.

When spring arrives, it’s time to clean out drainage systems that might have become clogged during winter. Check carefully for any frost heave damage—our freeze-thaw cycles can be particularly hard on walls. This is also the perfect time to replant any erosion-control vegetation that didn’t survive the winter.

Summer maintenance is generally lighter but still important. Keep an eye on irrigation systems to prevent overwatering near the wall. For timber walls, check for any signs of insect damage, which tends to become more apparent in warmer weather. Some walls develop algae or moss during humid summer months—while often just an aesthetic issue, you can clean these if desired.

Fall brings falling leaves, which love to clog drainage systems. Take time to clear leaves and other debris from drainage areas before winter arrives. This is also your last chance to make any necessary repairs before freeze-thaw cycles begin again. I always remind our clients that water trapped in cracks can expand when frozen, making small problems much worse over winter.

Winter maintenance is mostly about damage prevention. Avoid using de-icing chemicals near concrete or stone walls, as these can cause spalling and deterioration. Try to keep snow cleared away from the base of the wall to minimize moisture as it melts. And keep an eye out for ice dams that might direct water toward your wall when temperatures rise.

At Boston Landscape Co., we’ve seen how proper maintenance significantly extends the life of retaining wall construction projects. Many of our clients include regular wall inspections as part of their annual maintenance contracts—it’s a small investment that pays big dividends in the long run.

Frequently Asked Questions About Retaining Wall Construction

How Tall Can I Build a DIY Retaining Wall Before Professional Engineering is Required?

When homeowners ask me about DIY retaining walls, I always emphasize the importance of understanding height limitations. Most building codes allow walls up to 4 feet high without professional engineering – but that’s just a general guideline.

Think of it this way: a 4-foot wall might seem modest, but it’s holding back literally tons of soil pressure. Once you go beyond that 4-foot threshold, the forces involved increase dramatically, and that’s when professional expertise becomes not just recommended but necessary.

For taller walls, you’ll need to consider several additional factors:

- Professional engineering plans become mandatory

- Building permits must be obtained

- Construction techniques become more specialized

- Reinforcement systems (like geogrid or tiebacks) are typically required

Even with “shorter” walls under 4 feet, certain situations still warrant professional design – poor soil conditions, unusually steep slopes, or proximity to other structures can all complicate what seems like a simple project. I’ve seen many DIY walls fail simply because these factors weren’t properly addressed from the start.

At Boston Landscape Co., we help homeowners determine whether their specific project needs engineering services based on an honest assessment of site conditions. Sometimes this saves you money; other times it prevents costly failures down the road.

Do I Need a Permit to Build a Retaining Wall?

Permit requirements vary significantly depending on where you live, but there are some common triggers that typically require official approval.

You’ll likely need a permit when your wall:

- Exceeds 3-4 feet in height (measured from the bottom of the footing)

- Supports additional weight like a driveway or structure (called a surcharge)

- Sits near property boundaries or public rights-of-way

- Changes how water drains across your property

- Forms part of a terraced system with multiple walls

Here in the Greater Boston area, each town has its own specific requirements. Lexington’s regulations differ from Stoneham’s, which differ from Boston proper. This patchwork of regulations can be confusing, which is why checking with your local building department is always the first step I recommend.

The permit process typically involves submitting detailed plans, possibly providing engineering calculations, paying the required fees, and scheduling inspections at various points during construction. It might seem like a hassle, but these requirements exist for good reasons – they help ensure your wall is safe and won’t create problems for neighboring properties.

Many of our clients at Boston Landscape Co. appreciate that we handle this paperwork maze for them, making sure all the proper approvals are in place before breaking ground.

What are the Best Materials for Retaining Wall Construction?

When clients ask me about the “best” material for their retaining wall, my answer is always: “It depends on what matters most to you.” Each material has unique strengths and limitations, and the right choice varies based on your specific situation.

Concrete blocks offer outstanding versatility and have become our most commonly recommended option in New England. They come in countless styles – from rustic, tumbled finishes that mimic natural stone to sleek, contemporary options. Their consistent quality and relatively straightforward installation make them practical for walls of various heights. The downside? Some styles can look a bit manufactured, and the premium designer blocks can get expensive.

Natural stone creates absolutely stunning walls with timeless appeal. There’s something undeniably beautiful about a well-built stone wall that actually increases in character over time. However, this premium aesthetic comes with a higher price tag and requires significant skill to install properly. Stone walls are an investment that can last generations when built correctly.

Timber walls bring warmth and a rustic charm that works beautifully in wooded settings or informal gardens. They’re relatively budget-friendly and approachable for DIY enthusiasts with basic carpentry skills. The trade-off is longevity – even pressure-treated timber typically lasts just 15-20 years, and they require more maintenance, especially in wet areas.

Poured concrete offers best structural strength and can be formed into virtually any shape. This makes it ideal for modern designs or situations with unusual space constraints. The finished wall can include integral color or texture for a customized appearance. The downside is that concrete requires extensive formwork and professional installation, and without proper reinforcement, it can develop cracks over time.

Gabion baskets – wire cages filled with stone – create a distinctive contemporary look while providing excellent drainage. They’re relatively quick to install and offer a unique aesthetic that bridges natural and industrial styles. However, their somewhat raw appearance isn’t suitable for every setting, and they require engineering for heights over a few feet.

At Boston Landscape Co., we help clients steer these options by considering their specific site conditions, design preferences, and budget constraints. For many New England properties, we often recommend concrete block systems for their excellent balance of aesthetics, durability, and value in our challenging climate.

Conclusion

Building a retaining wall is truly a blend of practical engineering and creative landscaping. Like the foundation of a good story, a well-constructed retaining wall begins with thorough planning and ends with those finishing touches that make it uniquely yours.

Retaining wall construction might seem daunting at first, but breaking it down into manageable steps makes the process more approachable, whether you’re tackling a DIY project or working with professionals like us.

Throughout this guide, we’ve covered the essentials that make for a successful wall. Proper planning isn’t just helpful—it’s absolutely necessary. Taking time to understand your specific site conditions, soil type, and drainage patterns will save you countless headaches down the road. The right materials for your project depend on your budget, aesthetic preferences, and the wall’s purpose—there’s no one-size-fits-all solution.

That foundation preparation we talked about? It’s not the place to cut corners. A level, well-compacted base creates the stability that everything else builds upon. Think of it as the difference between building on sand or solid rock—one leads to problems, the other to lasting success.

I can’t emphasize enough how critical proper drainage is. In my three decades of experience building retaining walls throughout the Boston area, I’ve seen more walls fail from poor drainage than from any other cause. Water is both persistent and powerful—give it a proper path away from your wall, and you’ll avoid the most common cause of retaining wall failure.

For taller walls exceeding four feet, professional engineering isn’t just a recommendation—it’s typically required by building codes. These walls face tremendous pressure and need proper reinforcement to stand the test of time. The investment in professional design pays dividends in safety and longevity.

Once your wall is built, regular maintenance ensures it will serve you well for years to come. Simple steps like checking drainage paths, inspecting for cracks, and managing nearby vegetation can prevent small issues from becoming major problems.

At Boston Landscape Co., we’ve built hundreds of retaining walls throughout Stoneham, Billerica, Lexington, Winchester, and surrounding communities. Each project has its unique challenges and rewards, but they all share the same fundamental principles we’ve covered here.

Whether you’re considering taking on a retaining wall project yourself or looking for professional assistance, I hope this guide has given you valuable insights. A well-constructed retaining wall does more than hold back soil—it transforms unusable slopes into beautiful, functional spaces that improve your property’s value and enjoyment.

For more information about our approach to retaining wall construction or to discuss your specific project needs, please visit our Hardscaping Services in Boston page. We’d be delighted to help turn your landscaping vision into reality.